Cnc g codes Artofit

G-Code for CNC Programming (2022 Update) Marti Deans May 24, 2018 8 min read This post is also available in: Italiano (Italian) Deutsch (German) You know what they say about fundamentals: learn them first, and you'll remember them forever. The same holds true for CNC machine programming.

CNC Turning (FANUC) GCode MCode SOLO CAD DESIGNER

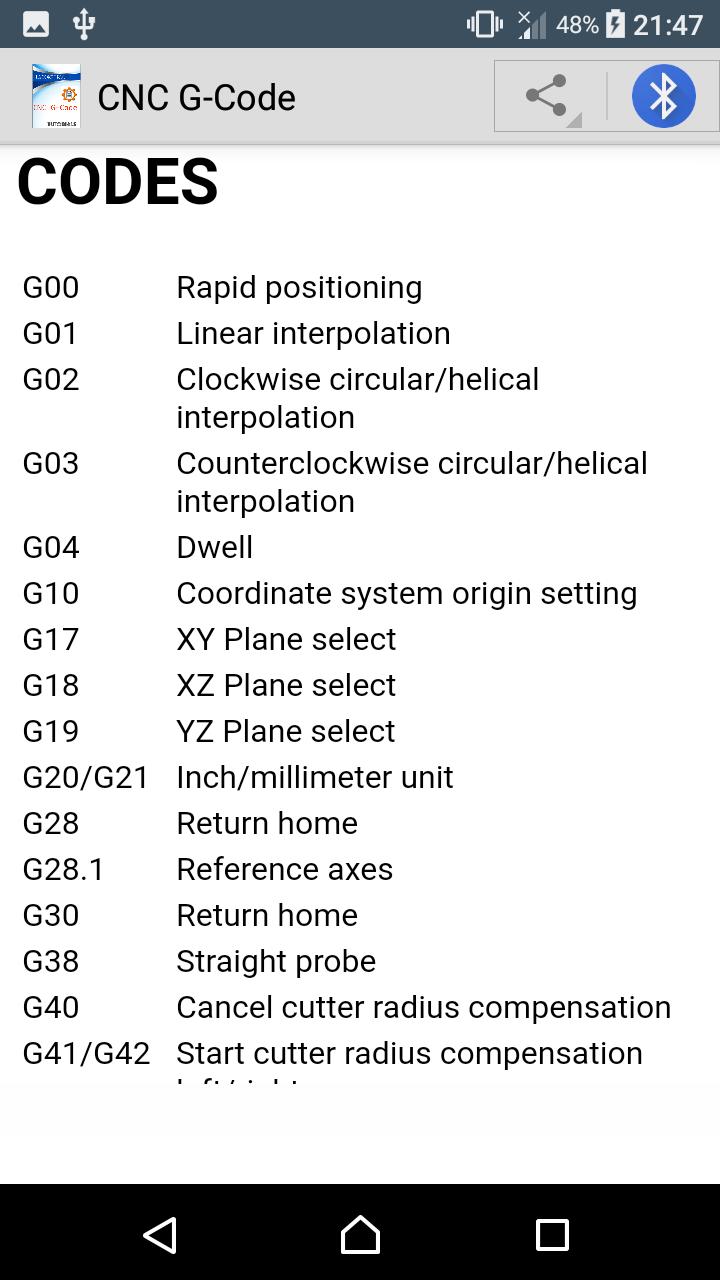

Often called rapid traverse. Learn more about the G00 code G01 - Linear Interpolation Move the CNC in a straight line to a specific location. The speed of this movement is determined by the feed rate (F). Learn more about the G01 code G02 - Circular Interpolation, Clockwise

Cnc G Code Software Free goodpolitical

Griffin Relief.ncc: 3D profiling job for a gryphon logo. HomeSwitchRearPanelEngrave.NCC: A control panel for my CNC electronics. SupportLogo.ncc: This g code file is a CNCCookbook logo for my tooling rack. G-Code Macro Examples Warm Up Program: This g code file runs your spindle and axes to warmup the CNC machine.

G code cnc demo reteraqua

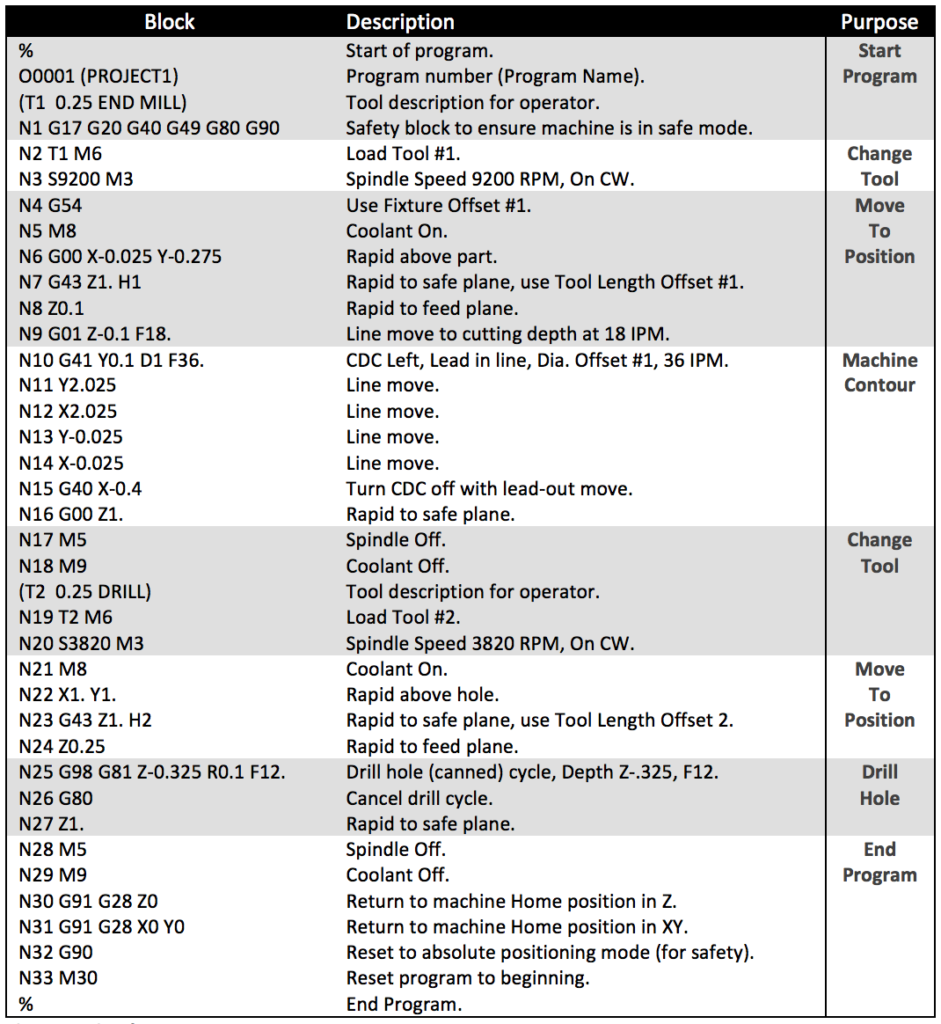

The most difficult task a Cnc newbie has to overcome is creating a G code program. There are quite a few articles on this website that will help you create your own programs but nothing beats getting your machine up and running on a project right away. G Code Files

Standard CNC G Codes Vertical and Horizontal Mills

G-Codes and Their Meaning. G-code is the name of a plain text language that is used to guide and direct CNC machines. For most modern CNC machines, it isn't necessary to know the meaning of G-codes since CAD and CAM software is translated into G or M codes to instruct a CNC machine on how to complete a process.

CNC G Code Programming A CNC Mill Tutorial explaining G Codes YouTube

G-code (also RS-274) is the most widely used computer numerical control (CNC) and 3D printing programming language. It is used mainly in computer-aided manufacturing to control automated machine tools, as well as for 3D-printer slicer applications. The G stands for geometry. G-code has many variants.

Скачать CNC GCode APK для Android

G-code (Geometric code) is a programming language by which a computer controls the movements of a CNC machine or a 3D printer. It defines the parameters like RPM of the spindle, feed rate, coordinates of the toolpath, tool information, fan speed, nozzle and bed temperature, etc.

Cnc Programming

G-code is a type of CNC programming language used for controlling the functions of a CNC machine that relate to the movement of the cutting tool.. It stands for 'Geometric code'. G-code consists of instructions that the microcontroller in the CNC machine can read and interpret. The instructions are then passed to the relevant machine part.

CNC Turning (FANUC) GCode MCode SOLO CAD DESIGNER

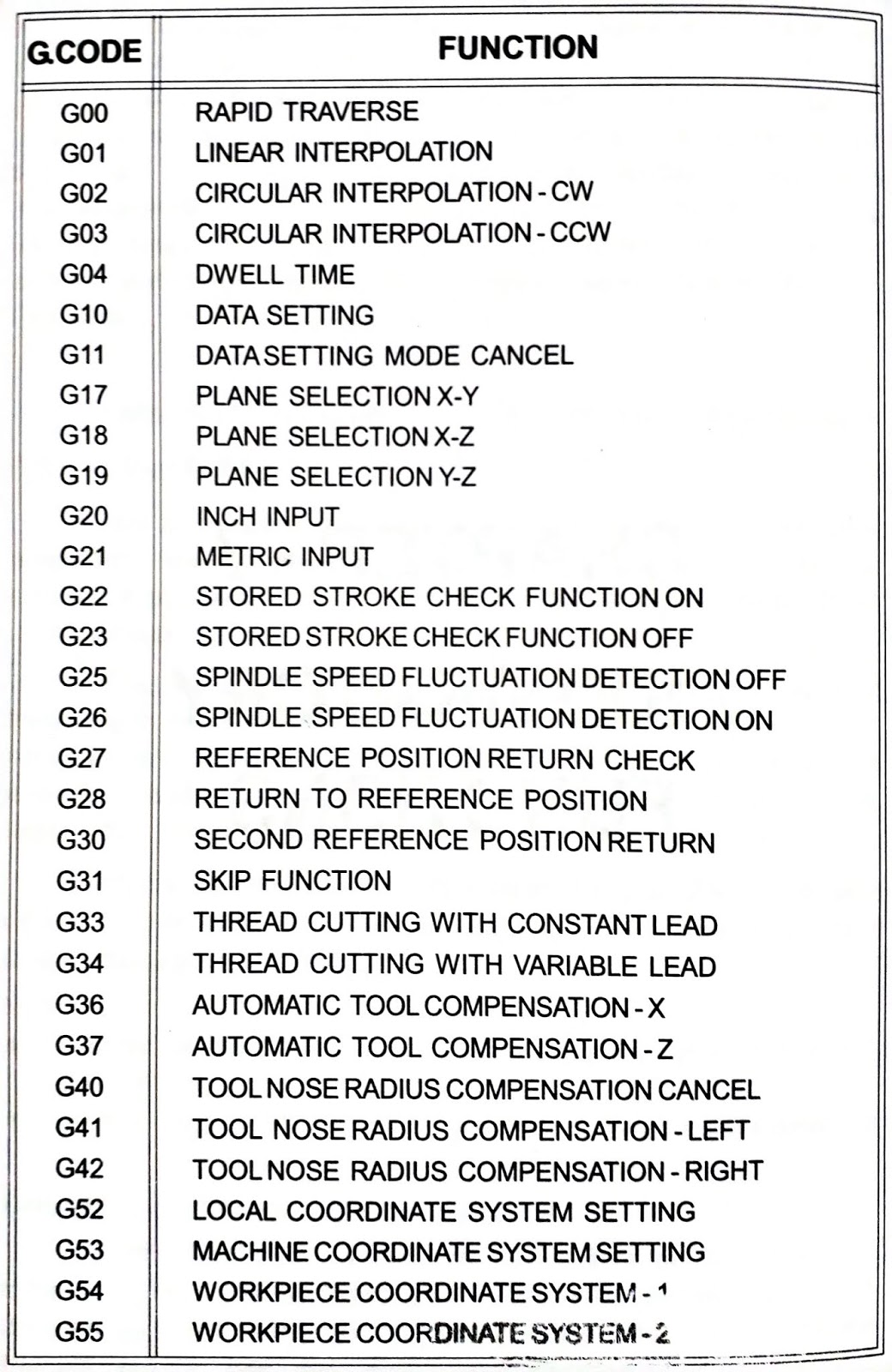

CNC G Codes T o control CNC machines we use commands called CNC G Codes. Although Different manufactures of the machine tool may adopt their own use for certain G Codes there is a core group that is common on every machine tool.

CNC G Code (1 of 2 CNC G & M codes infographics.) CNC Pinterest

G-code is a programming language for CNC (Computer Numerical Control) machines. G-code stands for "Geometric Code". We use this language to tell a machine what to do or how to do something. The G-code commands instruct the machine where to move, how fast to move and what path to follow.

Cnc Programming

What is G-Code? G-Code is the language used to control CNC machines. It's one type of CNC programming that CNC programmers use, the other type being CAM programming . CAM programs will generate g-code from a CAD drawing, but the end result is still g-code.

CNC GCode PDF

What Are G-Codes in CNC Programming? G code (also RS-274D) is the most popular CNC programming language. Most G code commands are in alphanumeric format and start with G which stands for geometry. They are responsible for the movements of CNC machines, telling the machine where to start, how to move, and when to stop when fabricating a part.

GCode for CNC Programming Fusion 360 Blog Cnc programming, Coding, Cnc

G-code is the common name for the most widely used CNC programming language. It was developed in the 1950s at MIT. The language is very "primitive" by today's standards. All the commands are represented by codes (G01, G02, etc..) and not by meaningful words.

GCode for CNC Programming Fusion 360 Blog

The word is the letter and the address is the number that follows. "G01" is word "G" and address "01". Hence, we call it the "F-word" because it uses the letter "F". This is the g-code needed to set your feedrate. For example, on a machine using Imperial units, "F100" tells the machine to move at 100 inches per minute.

Cnc Programming

Powerful online GCode Viewer to simulate GCode files. NC Viewer is the best free gcode editor for verifying CNC and 3D printer files.

CNC MILLING GCODE MCODE SOLO CAD DESIGNER

List of G-codes commonly found on Fanuc and similarly designed CNC controls G00 Positioning (Rapid traverse) G01 Linear interpolation (Cutting feed) G02 Circular interpolation CW or helical interpolation CW G03 Circular interpolation CCW or helical interpolation CCW G04 Dwell G10 Programmable data input G20 Input in inch G21 Input in mm